Metal Mesh: A Comprehensive Guide to Its Adaptability and Strength

Metal mesh stands out as an exceptional material highly regarded for its adaptability, durability, and wide-ranging applications across diverse industries. Whether in construction, industrial domains, or creative design landscapes, the unique traits of metal mesh make it an indispensable asset. This guide aims to delve into the world of metal mesh, exploring its uses, and advantages, and spotlighting its relevance in geotechnical applications like geogrids.

Understanding Metal Mesh: Manufacturing and Composition

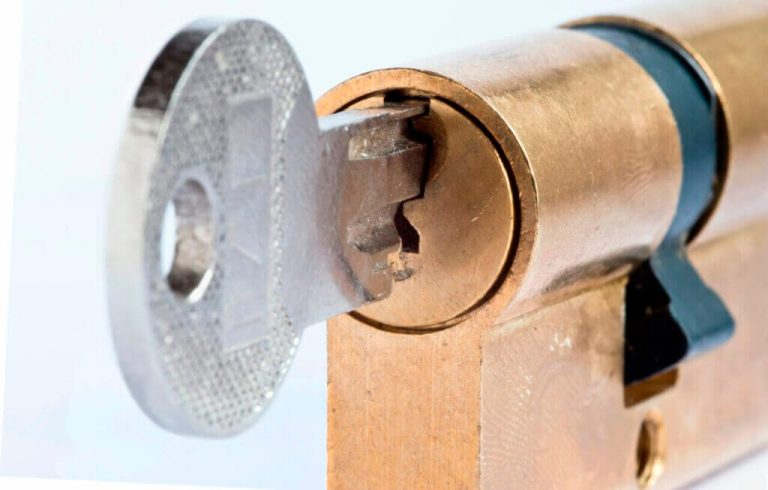

The metal mesh comprises interlocked or woven metal wires, forming a grid-like structure. Manufacturers utilize various metals such as stainless steel, aluminum, or galvanized steel. The manufacturing process involves weaving, welding, or extrusion, providing a range of designs and strengths tailored to specific applications.

Diverse Applications of Metal Mesh

Metal mesh finds multifaceted applications across industries. In architecture and interior design, it serves as decorative elements, facade cladding, or partitions. In industrial settings, it’s utilized for filtration, screening, or as conveyor belts. In construction, it reinforces concrete structures and offers stability in slope stabilization. Moreover, it’s extensively used in creating fencing, safety barriers, and protective coverings.

The Role of Metal Mesh in Geogrids

Geogrids, a specialized subset of geosynthetics, aim to fortify soil stability. Metal mesh, with its inherent strength and flexibility, is integrated into geogrids to reinforce soil, particularly in applications like retaining walls, road construction, and dams. The metal mesh provides structural support, curtailing soil erosion and enhancing load distribution.

Advantages of Metal Mesh in Diverse Applications

The utilization of metal mesh presents several advantages. Its durability and strength ensure longevity in various environments, resisting corrosion and extreme temperatures. Its flexibility allows for customization, addressing specific project requirements. Additionally, its transparent or open structure enables airflow, light penetration, and visibility, making it suitable for applications requiring these properties.